SP250 Rebuild Story

This is going to be a continuing story, each month as work is done; I will write up the progress and take photos. I am doing this to keep a record for my benefit so might as well share my experience.

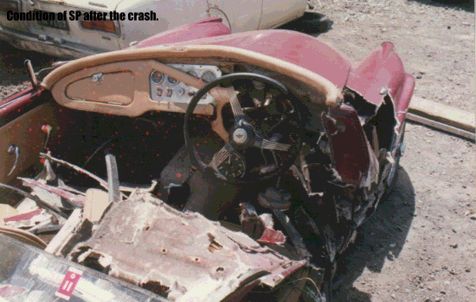

The story so far is—A long time ago (December 1989) the car was involved in an accident. The events just before and later are a story in itself but not one to be included in this narrative. The final outcome is that the insurance was voided and we had a seriously damaged car on our hands.

I am unable to find the original photos but for any that are interested they were published in the DLOC magazine, May 1990, Dart Talk April & August 1994. The body was demolished from just behind the front wheel to in front of the rear wheel right side, the damage going into the scuttle. Fortunately, the previous owner had installed a very strong extra chassis member to stiffen it up similar to the B spec. This obviously has saved the chassis from more serious damage. Not all the damage was from the accident, the towies managed to do more in moving the car, and I suppose they thought is was a write off.

For some time the car was stored under a tarpaulin at the end of our drive, time and finance were not available to do any serious work. I have always worked on the principle that I like to see the end before I start. After a while room was made to shift it inside and a start was made to dismantle. In the end the floor was cleared and the parts stored in every place we could find. With the chassis up against the wall I was able to get the Daimler V8 250 into the garage.

From the start, one of the problems we faced was the body. Though badly damaged it was repairable though it was the general opinion not an economic proposition, so a search was on to find a replacement. Some 10 years ago a company in the UK were making a replica SP250, but the cost at the time of a new body from them was beyond us. Recent enquiries have resulted in finding that that company has disappeared, and no one knows where the molds are. Like a lot of us budget and time constraints forced us to put the restoration on hold. Circumstances have changed now so the search for a body was resumed, in the end two were located in the UK, a complete B spec. with some damage is the one that is of greatest interest. Negotiations are going on and at the same time some hard to get parts are being sought, to be shipped at the same time.

After a lot of soul searching we have decided to rebuild the car as near to standard as we can, therefore as long as we can get the parts it will have the original gearbox and steering etc.

The way is now clear for a start so 30th October 2001 is a red letter day as the chassis was set up on two stools and Steven Carr who is helping when I need help, came round and we did a quick survey. From what we can see there is a lot of tweaking to do not all of it from the accident. Having seen this I wonder what the other SPs are like and how they would bear up under a close inspection. On the Thursday following the chassis was transported to Steven’s favourite body shop to wait for a space on their machine to get it surveyed and straightened.

While the chassis has been away, I have repaired a genuine steering wheel and fixed an indicator – horn assembly. The horn assembly was quite a job as I had two, one in good working order but with a broken skirt surround and one that was no good but with a sound skirt. To make one good one I made a wooden jig to hold the assembly then I took a coping saw and very carefully cut off the broken skirt, then did the same on the other one. Then using the jig I glued the two together, when the glue had hardened I filed off the surplus and sanded the lot to finish the surface. Next a coat of paint and when it is assembled with the chrome ring round the horn button I doubt if anyone will be able to see the repair. Much cheaper than a new one from UK at 140 pounds.

Monday 12th November, picked up the chassis and took it to Steven’s place to have the B spec. pieces we had fabricated many years ago welded to the chassis. We had taken the opportunity at the time to copy these from Steven’s car when it had a bare chassis and all the measurements were easily available. The chassis was examined for cracks and suspect welds; these were tended to, the chassis now looking sound. Wednesday we took it to Advanced Corrosion Treatments Ltd., Neilson St., Penrose for sandblasting and painting with a two-pot finish.

Tuesday 20th – Chassis back home, it looks a million dollars, a work of art, a sculpture, what a pity the I have to put all those bits and pieces on and then cover it up with a body.

Started overhauling the steering box, having trouble getting the rocker shaft out as must examine the stud that engages the worm, all looks OK so far. Started to clean and ready for painting the back axle, front suspension and any other parts that will be black parts. Have also been making up a frighteningly long list of parts that will be wanted. I have been shopping on the internet and making inquiries to anyone who just may be a supplier of parts for the SP, in the process have found some startling facts, when I finally do order, I will let you all know the outcomes.

Evenings have been spent going through all the Dart Talks and noting technical articles that will be of help. As I only have 2 tyres (now over 12 years old and will need to be replaced) and two bare rims, I have obtained 2 worn tyres to make a rolling chassis in the mean time.

The steering box has now been checked out, old lubricant cleaned out, all ready for painting.

It is a long time since my last article, lots of reasons (excuses) for the gap, an extended trip down to Invercargill plus distractions when we returned. All that aside in the last few weeks some progress has been made.

The brake calipers have been overhauled with new pistons and seals. Just Brakes of Onehunga did the job at a very reasonable price. New urethane bushes for the whole suspension were obtained from George Stock & Company and these have all been fitted. A major job to get the old ones out, in one case on the lower front I had to hacksaw through the bolt both sides of the arm and then cut the old bush out, then had to get a new bolt to fit. On the lower trunions the adjusting pieces had frozen in and had to be driven out, these have been freed up and are now working as they should.

Every part is being examined and repaired where possible, otherwise it is replaced. The chassis extensions that the bumper is mounted on were badly knocked about, but with some serious metal work I managed to get them back into what I hope is the right shape. Everything is being painted as each part is passed, this is a tedious job as most are coated all over this means that I paint half, let that dry then complete the other half.

The first order of parts now to hand including new rear brake discs. I wasn’t looking forward to the task of pulling the rear hubs as they can be very difficult to get off at times. I was lucky, I borrowed a large bolt on puller and they came off with only a belt with a 4lb hammer, I was prepared to use my large sledgehammer. The new discs have been fitted onto the hubs, and the hubs refitted to the axles. I’m using a torque wrench on most bolts to be sure of getting each bolt done up tight and even.

The rear springs are now back in place and the axle in fastened in position, a start has been made in assembling the front suspension, a bit of a hiccup here as I have found the right hand vertical link is bent. The tow truck people did this along with some other damage. The unit has now been dismantled and a mate with a press and a lathe will be pressed into service to correct this, I will then get it crack tested. One of the major problems is remembering after such a long time where everything is and in particular which are the correct bolts to use. I have bought in a quantity of new Nylock nuts to replace the old ones at final assembly, no use taking the risk of reusing the old ones.

Rear brake calipers are now in place, when the car was dismantled there were no shims here, they had just been bolted in place. I now have no idea if they were in the correct position or not as with the new discs the position must be different, all I know is the hand brake was never any good (very uneven wear) and shims were needed this time. What I did was clean the mating faces then bolt the calipers on, then using a heap of feeler gauges I measured the gap on each side of the disc, calculate the difference, halve that and that is the shim thickness needed. Find or make the necessary shims ( the micrometer came in handy here) fit the shims and check, I got them lined up within 2thou of true. Has to be better that before. The hand brake pads have been rebonded at great cost and the hand brake assembly is ready to be assembled.

Spent some time on the press and lathe getting the vertical link straight, then took it in to get it crack tested. Sad news, the vertical link has cracks in the threaded portion, so panic stations, wires are running hot on the net, contacting anyone who may be able to help, even put word out on the DLOC Forum. Lots of advice and some good leads to follow up, just shows that all is not lost as first thought. In the end located a replacement in the USA, this man doesn’t know it yet but he has made a friend for life. I wonder how long all this would have taken without the Internet. As an aside this part has a patent number cast into it, is this a Daimler patent or has this part been used in other British cars, someone with more time than myself could maybe do some research on this matter.

Even though I have overhauled the original steering box, I have never been happy with its condition so a search was made to find a replacement. I reasoned that there had to be many lying about out of cars that now have R & P fitted. In the end I located one with an adjustable steering wheel.(See article.)

This has now been dismantled and seems to be in good condition. I must admit it took me some time to fathom out how the adjustable wheel system worked. Simple really once you see how it all fits together, next was to make sure it would all go together at the final assembly. New gaskets were cut and everything cleaned again. I lost count of the number of times the box was pulled apart and put together again to get the whole thing to turn freely without play, but success at last. A final wipe over and then a coat of paint.

Having had bilateral knee surgery I cannot kneel and have difficulty getting down and up off the ground so I must avoid having to work under the car if possible. To help this I have a plan to assemble the chassis complete, with everything in place, this includes the exhaust. I have to decide if I temporarily use the cracked vertical link to create a rolling chassis and then replace it when the new one comes, all these decisions are so tiring.

A lesson learned. I had the hand brake pads rebonded as I said in the last issue, my mistake is I should have measured the thickness required as when I came to assemble the hand brake they were far too thick by at least 2 – 3 mm. This is partly because the new brake discs are much thicker than the old ones. After a lot of work getting them to go in they have ended up almost the same as the old ones were, I could have saved a lot of time and money.

Before I go any further I must say that I’m not a motor mechanic but have spent most of my life in the maintenance of machines in the textile and garment industry, this includes the design and building of specialist plant. I have an aversion to employing outside tradesman as I have found that I never get what I want done to my standard, at the same time I know my limitations as to my physical abilities and the equipment I either have or have access to. A case in point has just arisen with the back axle.

Not long before the accident we had the rear axle over-hauled with a new crownwheel and pinion fitted, this by a well known specialist firm in this field because I was not game to tackle this task. After I had fitted the new brake disc on the LH side, fitted the calipers and was in the process of assembling the hand brake I noticed that there was too much end float in the axle, .025 to be exact.

The book says .002 – .004. This was not wear as the car had not been anywhere of note between the job being done and the accident, it had not been done right in the first place. Nothing for it but to borrow the puller again, source a .010 shim and make it right. Have I made my point, don’t take it for granted that what others do for you is right, check things if you can.

My new American friend arrived yesterday with the vertical link and what I feared has happened, he has bought the wrong one, the LH instead of the RH. He has left it here and is sending the RH one over when he returns home. Take note it is for sale.

Have at last finished getting the hand-brake system all in place and working properly. It has taken many hours to do something that should have been quite straight-forward, so many things had been changed, and in effect butchered, that I had to almost rebuild every part. Even the new cable from the Spares Club was over 50mm too long and had to be shortened. (Spares Club take note) I am now confident that it is as good as it can be and that there is a ton of adjustment for the future. Hi-Tech Brake & Clutch, Melrose St did the shortening.

The brake piping, except for the very front, has been put in place and new ½ saddles made to position it on the chassis. The correct RH vertical link has arrived and it has been fitted into place.

All the exhaust parts have been sorted and cleaned, they are stainless and have scrubbed up quite good, won’t make the car go faster but will make it easier to work on. New rubber mounts have been bought, 8 in all, nearest I could find were an Austin – Morris part from Woolf Mufflers, not quite right but can be packed to suit.

A couple of friends (what are they for?) who came to dinner at our place were bribed to help me lift the bare block into place to enable me to get the exhaust system into the correct position. I will just sit the heads with the manifolds onto the block to make sure that it will be right when the motor is finally installed. This will also help to get a measurement for the drive shaft that will need rebuilding as it was altered to suit the Jag box.

Next jobs are to fit the rest of the steering mechanism, the front hubs with new bearings, then the front calipers. Still have to find out just where the petrol pipe actually runs. When that is done the chassis will be almost ready for the body. Should have some photos with the next episode.

The exhaust mounts have now been straightened and painted, the new rubbers fit OK with a little adjustment and the whole system assembled for a trial fit. The left hand tailpipe lined up correct, but the right was finishing at a very odd angle so needed some bending to get it the same as the other side. I then marked in various places to show position and where the bending was to be made, took an offset measurement and I headed for Woolf Mufflers, who I knew had a bending machine. Tongue in cheek and on the basis of all care no responsibility we made the bends, when home and fitted, it couldn’t have been better. You have to be lucky sometimes.

The block was in place with 2 studs lightly screwed in, the heads on and the exhaust manifolds held on buy a couple of nuts. The whole system was now dismantled and then reassembled, this time all the slip joints were coated with exhaust sealant, all the clamps were in place and tightened, all the mounting bolt and nuts tightened, job well done. I have to say that this was a big enough job refitting an exhaust system from the top with the body off. For the home DIY with the car on axle stands, to fit a new one from under the car with the body in place must be just so much harder.

The rear bolt on splines have now been bolted on, even this caused me some trouble. I am fairly careful where I put things like nuts etc as I’m working with them. In this case I was too careful and couldn’t find the RH ones. I searched off and on for 3 days and was starting to think I had lost my marbles as I knew they had to be close at hand somewhere, in the end I found them. I had put them in the space where the rear shocks go and then bolted the shocks on top of them without noticing them, not losing my mind after all.

The steering system is now in place, the box etc is in only temporary as it has to be removed to get the body on. I intend to borrow another idler to fit in place of the steering box so the car can be moved about while fitting the body. The long bolts used as spring compressors are still in place, this is to try to have the ride height as if loaded so when the chassis is on the ground I hope to adjust the wheel alignment as near as is possible. The bolt on splines are now on and the wheels in place, the only thing now missing off the chassis in the petrol pipe, still have to find out where it starts and finishes.

The day had to come, the chassis was lowered off the carpenter’s stools, quite a task, had to be taken in several bites, but on its wheels at last. First time at least part of the car has moved on its own wheels in over 10 years. It was pushed outside for some photos and to clean up the garage floor. Didn’t realise just how low it is, to work on it on the stools certainly save my back.

A rough check on the wheel alignment and then the front shock will be fitted, that will almost complete the front suspension.

Procedures are now in place to get the body and some bits shipped from the UK, in the meantime lots of work to be done. The difficult one is to straighten and assemble the windscreen frame, for this I have to make a pair of joiners for the bottom, I have worked out how I’m going to tackle this and will describe it next time, if it all works out OK. Another job is to make the wooden frame for the dash. I have 2 both with the RH third missing, quite a complex bit of woodwork but shouldn’t be too much bother.

The chassis is now almost complete, front shocks fitted, the lower bump-stops were a bit of a hassle as there is no weight in the chassis to compress the springs. I got around this by holding the chassis down with a tom from the ceiling of the garage and raising the stub-axle with a bottle jack. I still have to find out where the petrol pipe starts and finishes. Arranging to get the body shipped from the UK, a bit of a hiccup here as the shipping company now want the thing crated, something not mentioned up to now, but all in hand.

I have spent a considerable amount of time making the joining pieces for the windscreen frame. These I have cut from 3/16 flat steel with the extra offset brazed on. A lot of work with the hacksaw and file. Found out the hard way that the hole spacing on bottom ones on each side are different, but managed to save having to make a second replacement one. The fastening screws are 2BA ½” long. Considering the very corroded originals I had to copy, I think I have done a good job- even if I do say so myself. The bottom frame member was badly distorted in the accident so have had to do a lot of work to get that to line up with the glass. Have to wait for the screws to arrive before I can assemble the frame and really see if my bending etc is up to standard.

As a result of the crash almost half of the dash was turned into kindling so a new one has to be cut out of plywood. Not wanting to buy a whole sheet of 15mm ply I made several phone calls trying to find where off-cuts of ply can be purchased. In the end I found “Plywood City” out in Otahuhu. They have a huge range of plies and will sell off-cuts. And do it while you wait. One of our club members who is doing a partial rebuild loaned me the dash out of their car to copy, this has enabled me to fill in the missing parts much easier. Cutting out was a straight forward jig-saw job, there are some shallow rebates that were done with the router, holes marked, counter bored and drilled. I will have to follow the return of the borrowed dash to see what and how some of the mountings work. I am making up the threaded fittings as mine are missing, 4– ¼” NF & 2 – 2BA, just have to cut 22mm discs of 18g, braze the nuts on and drill the small holes for fastening. There are special fittings for fastening the padded dash on but I will let the trimmer fit these as he may have something different he wants to use. The hinges and lock for the glove box are all OK, so will be transferred.

It seems as if the body from the UK is still at least 8 weeks away and I’m running out of preparation jobs to do so not too sure when the next work will be done.

It seems a long time since I had anything to write about, it’s the 15th October and I’m still waiting for the body to leave the UK. The shipping people seem to be shifting the goal posts all the time, every time we think we are ready the find something else to change, I’m sure John in UK is wishing he had never heard of me.

I have been looking for a suitable material to make the packing pieces that go between the chassis and the body, something that I can shape with the equipment I have. It seems all sorts of material has been used from hard rubber to aluminium, in the end I have settled on PVC sheet ¼’’ and 1/8″ thick plus Formica for shims. I searched around for a supplier of PVC sheet and in the end was directed to the warehouse of what must be the major supplier. A huge selection of plastic in all forms but seeing my needs were so small I was directed to their rubbish bin where there were quite large pieces of just what I needed for the taking, the price was right too, free. It is true about one man’s rubbish in another man’s gold. The minimum datum is ½” so will have plenty of selection to get the body settled right. This has been cut with a hole-saw in the drill press into 2″ discs with a 7/16″ hole, a very tedious job.

I have purchased a variety of bolts, all needed as the car is being upgraded to a B spec., included in this are 4 extra special bolts to hold the body on. The normal are special hex-head with a countersink part under the head. If this is turned off a standard bolt not enough head is left to put a socket on so I understand the usual practice is to build a fillet of bronze under the head and then turn that off. I have opted to use 3/8 NF countersunk Allen head bolts, off the shelf, must be just as good and much easier. All the cup washers for the chassis bolts have been cleaned, rust-proofed and painted and the 4 extra have been made from frost plugs.

The rubbers under the cup washers are at over 40 years old, really passed their used by date so I shopped round to get some suitable sheet rubber to cut these out of, managed to get some from Gasket Specialists in Ellerslie. After a bit of thought I used a hole-saw in the drill press and then punched the centre hole with a wad punch. The outer edge was cleaned up on the grinder. A good but dirty job done.

It’s now 31st October and the body is I hope about to leave the UK. Talk about a drama, the last hiccup was the shipping people wanting 345.00 GBP to move the crate from High Wycombe to London in the end our friend John is getting a local carrier to do the job for 135.00 GBP, this at the exchange rate today works out at $451.61 NZ for a move of what is really a very short distance. We should be very glad we live where we do.

Whoopee! Great celebrations, 21st November and I’ve just received news the crated body is at last on the move. Not too sure just how it is being transported, anything from a Chinese Junk to a 747, knowing what has gone before it will surely be the Junk. It’s taken almost 5 months to produce the body in a manner acceptable to the freight people, mostly due to lack of communication skills on the shipper’s part. It will be interesting to see if they can find something else to delay things.

Among the many bits and pieces that have been accumulated over the years is a driver’s side window winder that was purchased from Spares for the SP before the accident and was never fitted. Thought I had better check it out, so got the worn one plus the LH side and unwrapped the new one and find to my horror that the new one was no where near the same as the others. In fact differed in at least 6 places and in its original form would never work in the SP. After a lot of thought I decided the new one could be altered and be made to fit so set about making one out of two. This little task took over 8 hours and I was fortunate that I have a gas plant, tools etc to enable the job to be done. Either I was very accurate or lucky but I now have a good pair of matching winders. I have since been told what I had is what is available, not too sure what the new one was actually intended for. If anyone out there has a similar problem if they contact me I will try and explain what was involved.

Preparation so far has been to take the radiator into National Radiators for re-coring; the new core is going to be a later type that I’m told is 20% more efficient. I’ve also asked to have a something to divert the coolant from closer to the bottom of the RH. header tank, hope they remember to do that. All the pieces that need chroming are at North City Platers who have been recommended to me as doing a good job at a reasonable price, at least their estimate is very good – time will tell. The original inlet manifold had been butchered a bit when someone had replaced the T hoses with a mess of copper pipes and brass fittings in the process they tried to fit a screw fitting into the front, this would need a lot of welding to repair. Luckily another club member had two or three off the later saloons and I will use that instead. It has been sandblasted and is at the powder coaters to be done matt black. The water pump system has already be done black.

The gears for the gearbox have been ordered, three other SP owners have joined with me to have a set made, so a small production run of 4 is in progress. I e-mailed twice to a major supplier of Daimler parts in the UK to see if they would like to join in with this run as the price is very good for one so multiples should be a lot less. Didn’t get a reply of any sort.

I’m reclaimed my engine building stand and a start is being made to get the necessary parts that I’m needing, the heads will only need a good clean and the valves re-seated as it was done not long before the accident. I could attempt to use the old main and big-end bearings but as I’ve lost track of which are which new one will be fitted, the crankshaft has been measured and the correct ones ordered.

Mid December and things are starting to get moving, the radiator is finished but National Radiators forgot to install the deflector in the RH side so it will be interesting to see if the new core that they say will be 20% more efficient really works, if there is an overheating problem they will redo the job for free. Total cost $429.63. Their opinion is a shroud is needed to get the best from the cooling system, I’ve seen one listed in a parts catalogue, I just may have a go at fabricating one if time permits.

The heads have been dismantled, the ports cleaned, the valves cleaned all over with a wire brush in the grinder. A little tip here, I took an old small screw driver, rounded the blade and heated it with the gas torch and bent about 8mm to a right angle, this proved to be the best tool I’ve ever used for this tedious job of decoaking the ports. It scrapes going in both directions, got into all the corners. As mentioned earlier the motor had had very little use since it had been rebuilt so all that was necessary was to lap the valves in and put it all back together again.

A heap of parts now to hand so a start has been made in rebuilding the motor, new mains fitted, the clearance has been checked with Plastigauge, spot on at .0025″ to .003″, big ends the same. The crank is now in place with new locking tabs under the bolts and new nyloc nuts for the bigends, rings +.020 purchased from Johnsons Piston Rings in Penrose, correctly gapped then fitted to the pistons and installed into the block, all dry. Only the minimum oil has been applied to the crank journals to avoid any oil getting into the bores. The motor is very tight.

29th December, received word the boat with our crate on has arrived in Auckland, couldn’t have been on a Chinese Junk after all. Now we have to wait and see if MAF have to get involved.

The block, tappet gallery, timing cover and front mounts have been painted. The sump is now bolted on after a good clean, used Loctite 515 on all surfaces, expensive stuff but well worth it in the long run. I wanted to get the bottom end finished so I will have no need to turn the motor right over in the future and therefor avoid any oil getting into the dry bores. This happened on a saloon motor I did some years ago that resulted in the rings not seating, in the end I had to strip it down and start again. Screwed in all the head studs and decided to start with the RH head, the 2 rocker-shafts were dismantled, cleaned, tappet adjusters loosened off, the whole lot reassembled and held together with a tie. The gasket ( .060 thick, as the heads had been planed at least a couple of times to my knowledge) was coated with a gasket cement, everything installed in place and bolted down gradually to 40 ft lbs.

A start was then made on the LH side, exhaust rocker shaft processed then trouble on the inlet one, it was bent, not a clue as to how, but more shocks to come. Rang a good friend who I knew had a lot of stuff under his house, yes he had a full set, so off I go with the old shaft to check these out to be puzzled as none of them seemed to be the same as my one. It was not until I got home again I found that someone had installed an odd shaft the wrong way round, this puts the oil holes were in the wrong place. This would mean that oil had not been getting through to the rockers but instead would have just poured out through the springs. Thankfully, near enough is not good enough with me and this was found. Just of interest the previous engine work had been done by an accredited mechanic who probably did what I could have done which is clean the rocker shaft assembly without pulling it to pieces and therefore would have missed this mistake. As a final check I squirted some oil into where each of the banjo bolts go and put pressure on with compressed air to observe where the bubbles came out, all correct at last.

Things to watch, inlet and exhaust rockers and shafts are completely different, on some the floating trunion and that end of the shaft are not drilled for the oilways so left cannot be swapped with the right.

Left the engine for a full day, then re-torqued the heads again, adjusted the tappet clearances then to be very sure checked it all again. I will have to reposition the motor on the stand as where it is I cannot get the oil feed pipes to the heads on. My intention is to couple on the oil pressure gauge, put some oil in the sump and using a fitting I have made use a battery drill in reverse to drive the pump to check all is well in the lubrication area.

The rocker covers were a bit of a mess and, as these are a feature, they needed a lot of work to get them to the polish stage. First I put some water with a little detergent in a large tub and set to work with wet and dry sandpaper until all the bad marks were cleaned off, finishing with 400 grade. Then after drying, onto the buff on the grinder to finish off, now looking great.

Still have to fit the brake-pads, but before doing so I have purchased some 3M stick-on product that I have been assured will eliminate brake squeal, time will tell if it is any good.

Now 8th January, body and parts cleared by customs but yes MAF want it steam cleaned, more delay, bit of a worry, so intend to be sure I’m on hand while it is unpacked and processed as if it is not handled right it could get seriously damaged. Not sure if brace straps across the top of the doors have been fitted so I will take two strips of ply and tools screws etc to put some in place. The steam-cleaning could save some hard work as the flaked paint should come off in the process.

While waiting for the body I have completed another of the tasks that needed to be done. The hood bows were distorted on the driver’s side as result of the accident and required quite a bit of attention. I made up a jig to get the right width of the mounting brackets, ground off the pivot rivets at the bracket, RH side only, this needed heating to straighten, then bolted the brackets to the jig. By using the gas set in some places, lots of hammer and a flat iron and judicious use of a large sash-clamp I think it is as close as is possible to correct. Mind you, I have not a clue as to whether it was correct in the first place. Now have to replace the pivot rivets and give it a coat of paint and another job done.

It is now 14th January and still waiting to get the body, it seems that used car imports are more important than a little job like ours and when dealing with a bureaucratic outfit that has a monopoly all that can be done is to phone each day to enquire.

Happenings since I finished number 7 – Thursday 16th January, sick of being fobbed off by the Port Authority where the body is for steam cleaning so approached the shippers about the possibility of moving it to another place. MAF Ok’d this so it was shifted to Ag,Stop, what a different in attitude, I was asked to be there at 8 am the next day to unpack and prepare it so they could do the job. All done by 10.00 so it was arranged to have it delivered to our place on Saturday using a truck with a Hyab.

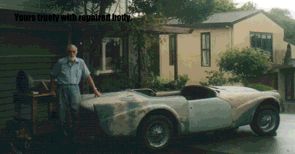

Set to immediately to alter and strengthen the base of what was left of the crate to use as a dolly, (it had come with 4 large casters, by the holes in the middle it started out with 6 but the centre two have been torn out and lost in transit) and lifted the body 6″ so the sills can be scraped. It is now 4th Feb and my wife and I have spent many hours scraping and sanding so I can now describe what we have bought.

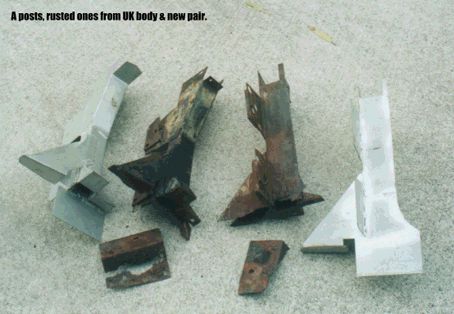

Ex factory the car must have been burgundy and at some future time has been repainted British Racing Green. In general there seems to been no serious accidents but over the years many minor dings that have just been bogged over leaving the glass with cracks, these will have to be ground out and properly repaired. The serious part of the fire damage was what I expected but what was describe as scorched paint was in fact paint baked right through to the glass and this covered most of the body. The baking had the effect of causing the paint to harden like concrete and is very difficult to remove. The bonnet has at least 6 areas of serious stress cracks and these are only the ones I have investigated, pity as it fits really great. Will use the one off the original car if it fits OK. Even though the boot lid seems sound it is badly burnt so will use the one off the old car. The worst find was that the bottoms of the “A” posts had completely rusted away, this was never mentioned and seeing the condition of these I hate to think what the chassis it came off of is like. The fastenings for the “B” post right side were also rusted away, this was caused by a hole in the wheel well that I think had been there since new allowing water etc to enter the cavity. The shell has been stripped of everything, even to the point of breaking off bolts and screws to do the job. I would say the car had had a fairly hard time of it, no major prangs but a number of minor dings that were not repaired but just patched up and re-sprayed over, these will all have to be repaired properly. To be honest if I had known the whole extent of the damage I would have looked elsewhere to see if there was a better offer, as it is, it is here now and we must carry on regardless, it is still a better bet than repairing the original body. I suppose this is what you get dealing from 12000 miles.

After the accident 12 years ago we had Steven Carr fabricate for us, at a considerable cost, all that was needed to make an A spec. into a B spec., we were hoping to be able to offer these for sale but virtually all will be now used to replace the rusted parts. Steven says now, he would not want to repeat that job so we were lucky as even if they are available it would cost a small fortune to source it all today. The new “A” posts had no holes drilled and the fittings for the door hinges still have to be made and attached, this has almost been done, just a trial fit and then paint it all before permanently fitting in place. In the meantime still trying to get all the old paint off and down to a solid acceptable base.

One set of parts we are missing is the 8 pieces for the door locking mechanism, the ones off the original car are some odd ones and require the doors to be altered, plus the RH one was badly damaged in the accident. I managed to trace original ones in the USA some from Carl Christiansen and the rest from John Carey who it seems has a huge inventory of SP parts. Anyone interested his e-mail address is or phone 978 356-4745, I think there would be 001 in front of that. John is a bit lax in the e-mail side of thing but he does answer in time.

One little task we have done for the Club is go to AC Fibreglass where the moulds are stored to locate them all, and take an inventory, we found them all except one, number 19 on the list. It still could be there, but just in case has any member out there and has it please let the committee know.

It is now Saturday 1st March, a red letter day as we have now removed all the paint off the body, doors boot and bonnet, right down to the gellcoat. I have certainly lost track of the hours my wife and I have spent on this job, all done by hand with a tungsten carbide scraper and sandpaper, we tried several power tools but in the just honest toil did the job better and faster. Some might say we have gone to too much trouble but this is the only way to find all the areas that need attention. As well when we come to prepare for painting the whole surface should be of the same density, no hard or soft spots.

There are a few things that have to be done before the body can be permanently bolted to the chassis, firstly the hinges cleaned, a surprise here as they have steel pins, not brass as you would expect on a Daimler. The area where the front of the body is bolted to the chassis has been rebuilt as parts of it have been torn away, plus a couple of small glass repairs in the engine bay. The body has been tipped on its side and the whole underside, has been cleaned and except where I know panels to be replaced, has been painted with underseal, the new parts will be done after repairs are completed.

The doors have been remounted and aligned, had quite a struggle with one hinge, couldn’t get it to move out far enough out so the door was flush with the body. Found out the floating nut plate was being stopped by its clip, solution hacksaw about 2mm off that side. Still not enough, then remembered that one of the hinges had a packing piece between it and the door, since lost, so made and fitted a metal piece, perfect.

18th March – another red-letter day, the body lowered onto the chassis. Now the tedious work starts. First up was to pack the side rails, these were part of the B spec conversion and were just blanks. Sorting the packing was quite a task, the fact this is not the original body on the chassis made this a big job. In the end I actually had to have three goes until I was satisfied that all was aligned as good as was possible. Particular attention was paid to the position of the B posts. Now the 4 holes for the hold-down bolts that go through the side rails could be marked, then off come the rails again. Pieces of 16g galvanised iron, cut a neat fit to go inside the rails were wedged inside and the holes drilled through. The inserts were removed and 3/8 NF nuts were brazed to the under side. The inserts were then put back inside the rails and temporary bolted in places so it could be pop-riveted, this is all that is necessary to hold them in place. The B posts were loosely bolted in place, then back onto the chassis again, everything tightened up and checked

Next the sorting out of the packing between the chassis and the body, after a bit of thought I decided to cut some wooden wedges and lever up the body as required and put the wedges in place until the doors etc all fitted OK. I then levered the body up a bit more so the packing could be slipped into place. As my packing was in several pieces and as each position needed a different combination I used the hot glue gun to tack them in a pile before pushing them into place. This made it much easier to align the packing to the bolt-holes. Knocked out the wedges out and then bolted down starting at the A-posts, had to adjust a couple of packing, but this method seems to have worked out OK. With my wonky knees and my difficulty in getting up and down off the floor this fitting the body to chassis was a hard job even spread over several days.

Fitting the locks was the next job. First up what to do about all the remains of the screws that were holding the anti-rattle fittings in both the doors and the body, these had either been broken off or the heads roughly drill off. These screws are 2 BA, and as these seem very hard to get I decided to go up to ¼” UNF knowing I would have to deepen the countersink on the fittings, so for a start drilled and tapped the ones on the doors. I went out and purchased the 16 ¼” UNF countersink socket head screws, I decided stainless ones would be better, not cheap but will save having to get the heads chromed.

One of these fastenings have to float for adjustment but I have no idea which one, door or body, so right or wrong the door one are fixed on this car. The body ones were a nut plate glassed over, these had to be removed so with great difficulty the glass was cut away to get the plates out. It was now that I could see why the screws couldn’t be removed, they were a mass of rust. The nut-plates for the striker- plates were completely missing so I decided to make up a plate long enough to attach the floating nut-plates for both fittings (using the same principle as the hinge ones on the A-posts) and fasten it inside the body cavity.

With great difficulty the area inside the body was cleaned of excess glass to make it as flat as possible, a piece of heave gauge galvanised was shaped to be a good fit with a return to enable the completed fitting to be attached where it wouldn’t show. Nuts were brazed on and a trial fit was made to mark as near as possible where the striker plate and the anti-rattle fittings should go. New nut-plates were cut, drilled and tapped and the sheet metal pieces to hold then folded and brazed in place then large holes for the screws were drill through, this to allow for adjustment. The completed plates were then fastened in place and a start was made with a trial fit of all the locks.

It was now I discover that there is a huge difference between the left and right side on this body. The gap between the door and the body is at least 5mm wider on the left door then the right that was so small the standard anti-rattle could not be fitted in, so I had to set to and make up a special pin part that is 2mm offset. That was only the start but 2 days later after much putting and taking of small packings to be sure that the new fitting was hard against the inside of the body and there would be no deflection when things are tightened up all was set in place and tightened.

I am now satisfied that after a bit of glass repairs and the paint job done the lock fittings should go on without any trouble, we hope.

Well doesn’t time fly when you are having fun, it is now over 10 months since starting this project, I must admit there are time I wonder why I even started but can now see the light at the end of the tunnel.

In this funny old world of ours, wouldn’t it be great if everyone did their work properly. Now we are onto the job of repairing the cracks and general damage on the body. We have done a deal with our SP250 guru, Steven Carr and he is well on the job, part of the deal should make for an interesting project for Steven. Of the many minor and the one major area that is requiring attention, not one has been done properly. In most cases instead of grinding out the damage and glassing it over all that has been done is the area has been covered with filler, sanded off and painted. The worst place, high up on the LH front just in front of the screen, there seems to have been a hole about 100mm and all that was done is a piece of sheet metal was pop-riveted inside as a backing. The hole filled with some sort of filler with some stranded matter in it, then normal filler on the top and sanded off. What they didn’t do was repair the cracks that radiated out from the hole, some as long as 400mm. All this has been dug out and a proper glass repair carried out. We have counted over 7 places, large and small that need to be redone and this is not counting the many stress cracks. The bonnet we are using is the one off the crash car and it has been flipped, the repair on this was better but has also been redone, we’re not trusting any previous work.

There is a message here, if you have any damage to the body of your SP fix it properly in the first place or it may come back to haunt you in the future. Covering cracks etc with filler and painting is not even a short-cut repair.

Three panels to replace the worst burnt parts have been made by AC Fibreglass, the damage portions have been cut out and the new grafted in. One of the surprise finds was the RH outer door, this had delaminated right down to the bottom, possibly not caused by the fire, probably been like that since leaving the factory. Workers probably knocked off for lunch half way through laying up the panel and didn’t get a proper bond when they started again, this means a whole new outer door skin instead of just the top portion.

I’ve been checking up on some of the bits that are needed in the finishing of the SP and have discovered that the boot and bonnet hinges off the wreck are not the right ones, they are off a Morris Minor. These look the same at first glance and could be made to work but as one has a broken tip I decided to do the right thing and get the correct ones. After a little research I decided to get two pair from Barry Thorne in the UK. His catalogue that I have was a bit out of date, stating 24.00 GBP, they are now 26.00 GBP a pair, but they were here about a week after ordering. The total cost for the two pair including P & P and a bank draft was $192.00 NZ – a price that is more than favourable with what others I know have paid.

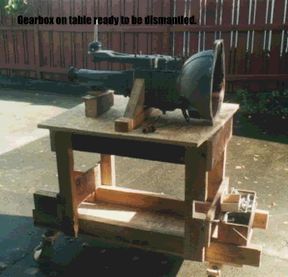

Another job I’ve done is to build a trolley to enable me to move and work on the motor and gearbox when these are reunited. To make use of it now I’ve made a removable table to fit over the trolley with a jig to hold the gearbox while it’s worked on. I don’t have a lot of room and this trolley with whatever is on it can be moved easily to any convenient place. All the bits of wood, wheels etc from the crate have come in handy. Surprising what can be made with a few scraps of wood, some screws etc …. anything to help make working easier.

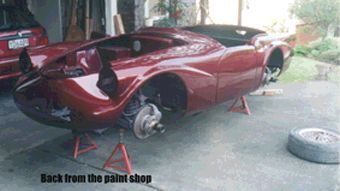

The car is now back home from Steve’s place and looking very good. Still some adjustments to do such as fitting the correct bonnet and boot hinges, getting the doors aligned and generally being sure any blobs of resin are removed. The quest is now on to find a painter, this is going to be a very interesting exercise.

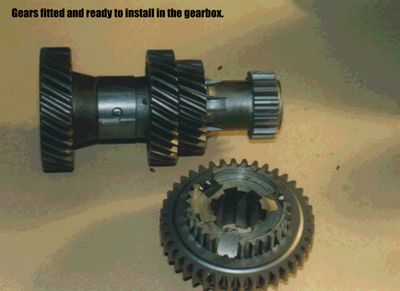

At long last the gears for the gearbox are finished, they look very good. The other three who joined me in getting this run done have been given theirs and the next job is for me to dismantle my box and fit mine. That will be covered in the next instalment.

My requirement for painters was to find one with the right gear who will do an honest job. I spent a lot of time on the phone and visited a number. I wanted someone with a presentable shop, a spray booth and oven, run by people you can talk to. An oven I felt is necessary, as I understand one of the common faults in a paint job is caused by applying another coat before the previous one has cured properly. Temperature is important here and being winter the use of an oven helps to avoid causing this problem. Some shops I wouldn’t give them a child’s trike to paint, one that came highly recommended talked in numbers that were off this planet, I wasn’t about to finance his entry into the next super yacht. A number said they would come and look but never turned up. In the end I picked Wright Car Painters, The Mall, Onehunga. Their premises were neat and tidy for a paint shop, they were interested and actually suggested I call in often to check progress. The car was sent there today 16th June 2003. They say something like 2 – 4 weeks for the job so it will be interesting to see if my choice is a good one.

Tuesday 24th June 2003. A start has been made on dismantling the gearbox, First problem is I broke the main-shaft circlip, which is very strong and difficult to remove. I have ordered one from the Spares Club but the first sent was wrong, so I have sent it back and am now waiting to see if they can supply the correct one. Things noted while dismantling: whoever worked on it last used Silicon on the gaskets, it was everywhere, hate the stuff especially when there is available far better products. Next job was to fit the gears onto the new lay-shaft. I understood that there has to be a small variation on the fit of the gears, of the four sets I had made I selected the lay-shaft that was a loose fit on the gears I had borrowed to use as a gauge, the others being a tight sliding fit. When I came to fit the gears out of my box they would not go anywhere near the lay-shaft, so a start was made finding the tight spots and honing these off to get a tight fit, even the amount need to be removed varied between the three gears. The conclusion has to be that there is a big variation in the fit standard of the internal gears made in the factory, the amount is obviously very small but critical all the same. This variation could be from the heat treatment the gears receive. In the end I pressed mine on using a bottle-jack with a heavy piece of timber under a brick arch to form a crude press, it worked. I will be interested to hear how the other three get on in fitting their new gears. I’m sure they will let me know.

Fitted the needle rollers using the dummy lay-shaft and fitted the assembled lay-shaft with the thrust washers into the box to check the end-float. This was a little more that specified by about 10 thou so as I couldn’t get a thicker one, I took a chance and sweated solder onto the rear one, cleaned it off with a file till it measured correct with a micrometer, checked it again until I was satisfied. I picked the rear one as I reasoned that by the angle of the skew gears all the thrust pressure is taken on the front washer. Note if anyone is ever short of a needle rollers let me know as I now have 48 good ones to spare.

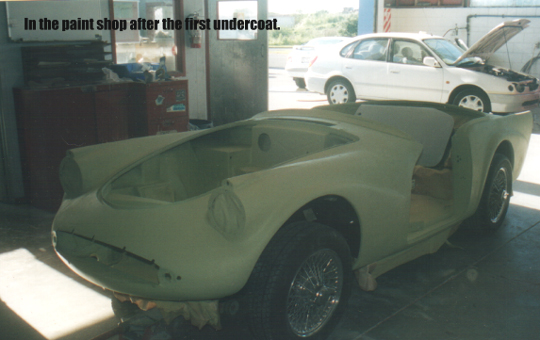

I have been over to the paint shop to look at the car and discuss progress. The agreed procedure is going to be firstly a spray with a 2 pot primer. Regardless of anything else this is a must as there is very little gel-coat left on the car. There are a couple of places where some thicker bog is needed so that is next, then the whole car is to be sprayed with a coat of Spritz, which is a spray-on bog and is needed to fill all the small holes where the fibre-glass has been repaired. Then the whole car is to be sanded with long-boards to get all the irregularities straightened out. Next another 2 pot undercoat, more sanding then, if all is OK, the final colour. Each coat to be left about a week to cure.

Made another visit to the paint shop to take over side-lights, tail-light surrounds and the grill to check the fit of these, just as well as one rear fin was a little low. Also they wanted the rubbers for the doors, boot and bonnet so a check could be made on the standard of the fit. Time was of the essence so I called in at the new “Para” shop in Carr Rd and they had the right articles. In talking to the proprietor he told me all the NZ shops are a new franchise affiliated to a large Australian group of retail shops in the same field. I asked him about grommets suitable for the thicker fibre-glass and he had one size in stock but said he could bring in any size I wanted. I had been told by other SP owners these had not been available in the past, will see what he can supply when I need them.

Unfortunately even though I wanted to get the gearbox assembled there have been other jobs for me to do so will cover all that and a full report on the paint job next time. Quite happy with the painters so far, their interest is very high as this is the first fibre-glass car they have done. Be interested to see the final cost.

I have had to put the gearbox aside while I assembled the windscreen, this is to enable the painters to check and, if necessary, adjust the fit to the body. To be honest this was a difficult and time-consuming job. I had a complete set of new screws even though I had rethreaded No2 BA some 3/16 Whitworth to use when I straightened the frame. Firstly I carefully measured the position of the holes in the bottom rail, marked them from the center onto the new screen to body rubber and punched them with a 3/8” wad punch. I then pointed the sides of the T in the rubber at each hole, this to help each one to start as each hole in the rail came up. Checked as carefully as possible the T slot and made sure the screw heads of the joining pieces were clear. Some recommend soapy water as a lubricant when inserting any rubbers into windscreens, I didn’t like the idea of using any water as the steel joining pieces rust out soon enough so I used rubber grease. This comes in a tube and is formulated so as not to damage the rubber in any way, something-ordinary petroleum grease will do.

After a bit of serious thought as to the method of assembly I decided on the following. I greased the first quarter of the screen to body rubber and the bottom rail, then started to thread the rubber into the bottom rail, got about 30cm on and couldn’t budge it any more. Pulled it off and applied more grease and started again got about 40cm this time but no more. After more serious thought I decided the T section of the rubber was just a little tight for the slot so I rubbed it down with some sandpaper and started again. It was still a struggle with lots of huffing and puffing but success at last. Next I trimmed the ends of the rubber to fit the frame sides, this was quite tricky as there are some funny shapes to cut. The joining pieces were firmly screwed to the sides top and bottom, I then threaded the side frames onto the rubber and loosely did up the end screw leaving the other one off.

Next I fitted the windscreen rubber onto the glass and carefully marked the center of the bottom rail and the glass, three new 5/16th NF bolts were fitted in the bottom rail. I put a liberal quantity of the rubber grease to the frame and rubber, then with help, lined up the two marks and started to install the glass. When we had the bottom in as far as it would go we started to close up the sides, a fine screw-drive was used to get the lip of the rubber over the frame. A rubber hammer also helped to close up the sides plus more use of the screw-driver, checking the top rail for fit. When all was in the right position the top rail was greased and pushed into place, all the screws were inserted and tightened. In fitting the top rail the careful use of a sash-clamp was very helpful even then getting the glass in was a two-person job. I have heard of a windscreen installer who replaced a screen without dismantling the frame, must have been a tricky job.

I took the assembled windscreen over to the painters with a template of the angle from the top of the doors. Put the screen in place and bolted the three bolt down, a quick check showed that filler was needed at the sides to get the right angle. This has now been done and a check today 15th July shows the car ready for the Spritz coat. By all appearances this is going to be one of the straightest cars around when it is finished. Now 28th July and the car is undercoated ready for a fine sand down then the final colour coat, could be home in about a week.

Now back working on the gearbox, first cut a whole set of new gaskets, no trouble here. When I was dismantling the box I checked everything I could to see if anything was worn and needed to be replaced. The only thing I didn’t do at the time was the clearances as described fig. H19, page H28 in the workshop manual. As mentioned in an earlier article I broke the main-shaft circlip and had two goes at getting the right one to replace it, in the end sending the broken one to the Spares Club as an example. Fortunately I didn’t get the broken one back as if I had used it to test the clearance as described I would have been in trouble. I threaded the 2 thrust washers and 2 bearings onto the shaft and tried the new circlip in the groove. It wouldn’t go anywhere near the groove. Out comes the micrometer and I measure the thickness of the 2 thrust washers. The 2nd gear one was .121” as specified but the 3rd gear one measured .146”, about .025” too thick. The conclusion I came to was both the 3rd gear washer and the old circlip were not genuine SP parts, a thinner circlip and a thicker thrust washer had been used to make up the difference.

I rang our friendly local SP Guru, Steven Carr, knowing he had a lot of bits and he kindly gave me a plastic bag of parts to sort through. There were several 3rd gear washers of the correct thickness so threaded one on and the clearance measured .010, the day saved. As an aside in the bag was a circlip that was .025 thinner than my new one, a trap for someone in the future.

A special tool is needed to fit the circlip, a tapered sleeve and a tube. There is a description of one on page H30 but be warned don’t make it to the dimensions they give, they are wrong, measure the shaft etc. Even though I have access to a lathe I decided to fabricate one. First a piece of ¾” ID tubing 2’’ long from the scrap box that fitted over the bearing spigot, then from some 16 gauge sheet a piece to form a tube about 1” long over that and a repeat of that again each this time ½” long. Position the outer ones to form a stepped cone, being sure to try for a fit on the shaft, light up the gas torch and braze the lot together. Next on to the grinder and work to take off the steps until a smooth cone is formed, polish with emery. I couldn’t find any tubing 1 ¼ “+ in my scrap box so cut another piece of the 16g 4” by 6“, rolled it to form a tube 6’ long. This is to push the circlip onto the shaft.

The lay-shaft had been in the box for some time so it was removed and the whole lot given a good clean. On gearboxes I have worked on in the past it has always been a juggling act lifting the lay-shaft into place so the dummy shaft can be pushed out with the real one. I put those little grey-cells to work and decided there must be an easier way. Before putting the lay-shaft in, I put 2 strips of heavy tape (strong cord would do) in the box with plenty hanging over the side, the shaft was put in with the thrust washers in place. Next the main shaft was inserted, the gears threaded on as per the manual, the circlip fitting tool was given a coating of grease, put over the spigot and the circlip pushed into place. It all worked a treat. The 3rd constant mesh gear was put onto the end of the mainshaft and the whole assembly was pressed into place. The primary shaft was then pushed into place now all was ready to lift the layshaft.

I had one short length of square tubing, but a piece of wood would do. This was placed on top of the box and the tapes were then tied tight over the top. I then cut two wedges and eased these under each end of the tubing until the layshaft was the right height both ends, see photo, the dummy shaft was pushed out then with out any bother. The dummy shaft I had was solid, others I have used in the past have been thick walled tubing, with them it is possible to put a rod through and lift the assembly that way. Having now done it both ways I think my latest method is easier and safer.

The rest of the box was then bolted up using Loctight 515 for the gaskets, the clutch actuating shaft installed and preparations started to marry the engine and gearbox. The new locally made gears seem to be A OK up to now – won’t know for sure until a test drive. The gearbox, then the table was lifted off the trolley, the motor lifted off the building stand and lowered onto the trolley. The 2 bolts holding the rear crankshaft seal at the back of the block were then tightened as I couldn’t get at these while the block was on the stand.

As mentioned in an earlier article the car had a Jag OD box fitted at the time of the crash. The bearing in the end of the crankshaft for them is ½” so it had to be removed, the SP’s is ¾”. Now normally this is not a big job, just pump a lot of grease into the hole get a piece of shafting the right size, introduce it into the hole and give it a good belt with a hammer and the bearing should pop out. Got a piece of ½” rod and tried it, no good as the bearing was very worn, and the grease just blew out, nothing bigger to hand so decide to solder a brass ferule to the end, cut from thin sheet and rolled. Only made it ½” long, should have been over 1” as I had great difficulty getting the hole filled with grease. The end would go right through the bearing and the piston effect was lost, plus always getting pockets of air and the hydraulic principle wouldn’t work. In the end I managed to get the bearing to move but had to put more grease in and be sure to get all the air out for each 1/8” of move.

I still had the original SP bearing and a check showed it to be as good as new so it was pressed in. Shows it pays to keep everything that may be of use at a later date. The oil pipes feeding the rocker shafts was now bolted on using new copper washers, the back plate for holding the gearbox was cleaned up and bolted in place. Next the fly-wheel was bolted on using new lock plates. I noticed one of the locating dowels for the gearbox was missing – no trouble just a piece of 3/8” rod , ¾” long tapped in and that job done.

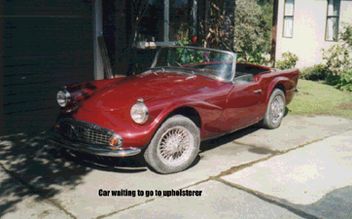

It’s the first of August and I am working to get as much preparation done so a start can be made in putting the car together when it comes back from the painters, which could be a week to ten days. The upholsterer says he will be ready about the end of August and I don’t want to miss my place in the cue.

The next job was to set the clutch in place. The new clutch plate came from a long time DLOC member who has only the early type of Daimlers that have the Wilson Pre-select boxes. He landed the disc with some other parts many years ago, it was in a Borg & Beck box the price marked $34.45, he was glad to get rid of it and I was glad to get it. Before I could fit the clutch I needed a clutch plate locating tool. I made this by turning one from a piece of cricket stump on one of those lathe attachments using a drill that Black & Decker used to produce. I have had one tucked away in a corner of my workshop, it did the job fine. The plate was put in place using the tool and the pressure plat bolted on, being sure to use bolts all the same size so as not to upset the balance.

I started to get the gearbox ready to bolt on when I realised I had not installed the new clutch release bearing, that done the gearbox was bolted into place and the starter motor bolted on also. The new gearbox mounts were then attached with the chassis plate. Not too sure if the whole assembly can be introduced into the body with the mounts attached, time will tell.

On all my older cars I have fitted a bypass oil filter, so even though this car will be for sale when it is finished, the one that was on the car is being refitted. For those not familiar with these, a small amount of oil is bled off the main oil line, passed through the filter and piped back into the sump. These have been around for many years, in the early 50’s I fitted a kit put out by Fram to our 1938 Morris 8 Sports. Then sometime in the 60’s a couple of West Auckland blokes designed and produced a model using a “Purex” 2 ply toilet roll for the filter medium. I bought and fitted a kit for the 1963 Singer Vogue we bought in 1967, I still have the fitting instructions. By the time we bought the 1969 Daimler V8 250 over 12 years ago, the manufacturer had closed down so when I did the engine job on that I managed to find one from a wrecker after a lot of chasing.

The operating procedure is as follows, the filter is changed at 1000 miles or sooner, down to 500 miles if only short trips are made, it then takes a pint of oil to top up the sump. The toilet roll absorbs the acids and any moisture from the oil as well as filtering out the sludge, it is amazing just how much sludge is removed in what is a short distance. I always changed my oil at regular intervals but it has been known for a motor to go for over 100.000 mile without an oil change and still have good oil pressure and performance, this when a good bypass filter has been fitted. The fact that these units have not been made for many years means that at present they are about as plentiful as rocking horse poo. I have got 2 to spare if anyone is interested, I would fit one in our newish Rover but there is no room under the bonnet.

I am hoping to get as much of the motor assembly done before it is put into the body so all that is needed is to couple up the necessary leads etc and press the starter. The next part of this is to make new heater pipes, for this I needed to know the position of the heater. I made a shelf to fasten onto the trolley, positioned from measurements off another SP then fabricated out of copper the necessary pipes. When we bought the SP it had a mess of screw fittings that have now been eliminated that is except the ones that had been fitted into the pump assembly. No T hoses, just 2 short hoses to the manifold and 2 to the heater.

The wiper system has been dismantled, cleaned and new grease put in. The old grease was almost non-existent, actually powdery, probably never been touched since new. A check of the speedo and rev-counter cables show these need to be replaced, have been done by Robinson Instrument Services in Sale St. The Bowden cables for the heater, choke and bonnet catch have been checked and lubricated. All the bumper mounts have been painted.

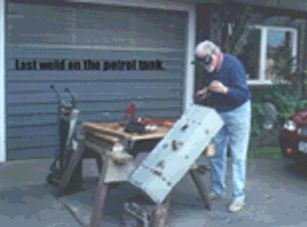

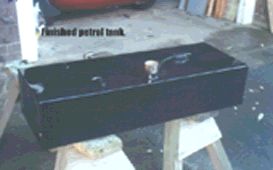

Next to receive attention was the petrol tank, the one out of the old car is obviously not an original, it has been made of steel sheet with welded seams but looks sound all the same. A good scrub on the outside revealed some minor surface rust that was attended to with some rust killer. I then took the gauge mechanism out, firstly to get a look inside, just as well as the pivot pin had seized, soon freed that, had a look inside all seems OK. Put the gauge mechanism back with a new gasket and gave the whole outside a coat of chassis paint.

Next work on the distributor, first I find the wire from the condenser to earth was broken and the other earth wire almost broken as well, have to replaced these. The felt oil wiper the lubricates the cam had disappeared so needed replacing. I cut off the rivet, then got a piece of heavy felt, cut a piece about 40mm long by 8mm wide, smeared both sides of the spring with “Arildite”, folded the felt round the end of the spring, then sewed it on through the old rivet hole. Looks like it will do the job admirably. The distributor has been put back together with new points and condenser, all set up ready to go.

It’s the 18th August 2003 and another red-letter day in the progress of the rebuild. The car is back from the painters and is looking very spectacular, Wright Car Painters in Onehunga have done a really great job. As a record they have taken dozens of digital photos of the whole process, definitely want the car taken over when it is finished to complete the record. The bonnet, boot lid and the two doors have been stored very carefully in our spare bedroom out of harm’s way. We have jacked the car up and given the chassis etc a good wash-down to get all the dust off. A start has been made in preparing the installation of the new wiring loom. I spread it out on a trestle table and with a wiring diagram to hand I am trying to identify what each of the branches are for, labelling each as I go.

As a spell from peering at coloured wires, I have taken off the spare steering idler and installed the steering gear. I had a new grommet for where the column goes through the fire-wall and managed to get this in with a huge struggle, then I had to enlarge the hole to get the column through. After all that nothing aligned up with the dashboard cut-out, so out it all comes. I took the grommet off and the first thing I find is that the hole in the fire-wall is at least 8mm too small for this grommet, also part of the body in the cockpit side fouls the grommet, no wonder I had trouble in getting it in the first time. Some careful work with a rasp to get the hole to size, a trim with the snips and it went in real easy, push the column etc into place, bolt it all up, a job well done.

The grommet specifications have obviously been changed so if grommets of any sort are to be fitted if pays to check that the size matches the hole.

Made another visit to our friendly “Para” shop, sheet rubber to make gaskets for the tail-light surrounds, they cut new gaskets for behind the lens of the tail and indicator lights. I also got some gasket packing for the heater plus something to put under the petrol tank plus some thicker rubber to make the packing that goes between the body and the side lights, the old ones are just too hard now to be used again. I bought some grommets and have found that the ones that have the narrow slot for sheet metal can be adapted for fibre-glass. I clamped the angle grinder in the vice and carefully widened the slot, there seems to be enough meat there to enable this to be done. Para had only one size of grommet for fibre-glass a small one.

Each day there is progress on the installation of the new wiring loom. I must admit I started this with some trepidation, it looked very daunting, but as time progressed things became much clearer. It would have helped to have another car along side to refer to. Some of the things that have helped are, I had the forethought to pull a draw-wire through when I pulled the old loom from the RH side, (I had asked for this part of the loom to be left in place) this made it easy to get the new one into place. When we dismantled the car all those years ago we had left all the fittings such as voltage regulator etc coupled, just unscrewed them all from the body. This left a mess of wires, but along with the wiring diagram helped identify a lot of things.

The new dashboard is now in place, the gauges and switches have been put onto the newly chromed dash insert and most if the wiring coupled to the terminals. The tail lights are also in place with new rubber gaskets.

As a spell from the wiring I decided to put the petrol tank in, problems, it won’t go in, too high to go under the fastening straps by at least 5-6mm. I could have cut a wedge out where the straps go but I have an aversion to working on petrol tanks, can be dangerous so decided to make up a new one that would fit. I worked out the material needed and ordered it from a local sheet- metal shop, 18g or 1mm electro-galvanised iron. I am probable lucky in that I have a small rotary sheer that will cut this heavy sheet, a gas welding plant plus some skills from my very early work experience that enable me to tackle this sort of job. Bending this gauge of metal by hand is very hard but is achievable with time and determination. A heavy iron bar, pieces of wood, clamps, lots grunting and pushing and hammering making lots of noise. I divided the inside into four with three baffles, these and the end pieces were bent on a wooden former. The whole lot was bronze welded including the fittings for attaching the gauge etc. When it was all finished it was pressure tested, this done even though from a visual inspection of the welding I was confident it wouldn’t leak. A coat of paint and I feel a job well done, just like a bought job. The tank is now bolted in place.

The new rubbers for behind the side lights have been shaped, the grinder is very handy for finishing off rubber to shape. A start has been made fitting the side and head lights, one side finished. One of the things I am disappointed about is that there are four parts of the new wiring loom missing, Both sides from the main loom to the head lights, from the loom to the bottom of the steering and the small part to the panel lights for rev-counter and speedo. Fortunately I still have the ones from the old loom. Went to fit the speedo and found the trip meter reset was missing, have taken it into Robinson’s for an overhaul.

Along with finishing the wiring the next big job is to make and fit mountings for the seat belts, will be able to slip the motor into place. Well that enough for now, Editor waiting.

The wiring is basically complete, had to get a new flasher unit, the only thing left to be resolved is the high-beam warning light glowing dimly when on low-beam, a bad earth in the light circuit some where, will take a bit of searching to find this one. The petrol pump and filter are in place with all new hoses, heater finished off. Distributor bolted in and timed using the light bulb method, all new spark plugs in place and all the leads connected. After some searching I found the oil for the gearbox I wanted, Castrol GP 50, unfortunately I had to buy 4 litres when I only need less than 1 litre so I have enough for three fills of a SP gearbox to sell if anyone out there is interested.

Bolted the re-chromed front grill, the front bumper extensions in place with the horns. The rear bumper brackets in place, the over-riders attached to the bumper and the assembly bolted up.

Preparation in hand to put motor into body, borrowed back the gadget I made and traded to Steven Carr that makes it easy and very safe to alter the centre of gravity while installing a motor, wouldn’t attempt it without that now, makes this virtually a one person job.

Took the gear lever off, hoisted the motor and it slipped in easy as pie, bolted the mounts down and gear lever back in place. Cut packings for the heater and bolted it in place. Made a trial fit of the radiator to find the mounting holes didn’t line up so out it came to slot the holes, second time all was well. I have made a point of running a tap through all threaded holes to clear ant paint etc out a bit of a bind but well worth the trouble in the end. Coupled up all the new coolant and petrol hoses. A bit of advice here, some days after I had the motor in I received an e-mail reminding me to attach the hose to the oil pressure gauge before installing the motor as this is almost impossible to get at after. I hadn’t done this but fortunately the position if this coupling has been changed on my car in taking the piping to the by-pass filter and this hose can just be coupled with some difficulty, I was very lucky. I was unlucky though as the hose was so brittle it snapped, so needed to be replaced. I did think of using hose as used in fish tanks but, as this has quite a low heat tolerance looked around for something more suitable. With Steven Carr’s help (he want some too) we located a 3/16 od. hose marked Nylon 12 (1200 series) from Hose & Couplings, Neilson St Onehunga, plus some 3/16 id. to shield it through the fire-wall. You literally have to use boiling water to attach the fittings, I had a T fitting that was the same as the gauge end, this helped hold and to retain more heat this end, it took several goes to get the fittings on fully.

Made up mounts for seat-belt attachment, these out of 3mm steel, decided to go for 3 point belts. Made sure that the attachments were very strong and well attached as they have to be certified by an engineer before the car can be re-registered etc. I managed to find one who made house calls. He passed the ones attached to the chassis, but as there are no specifications for anything attached to fibre-glass he would not pass the ones on top of the back wheel well even though he considered them to be, at a guess OK.

According to him they would have to take a strain of 1½ tons and he had no way of checking that. Can you imagine a strain of 1½ tons on your shoulder, over kill surely, officialdom gone mad. His advise was to go through the system with lap belt only and to fit the 3 point ones later, time will tell if that scheme works OK.

The drive shaft had to be shortened and balanced, it had been lengthened to accommodate the Jag box, it is now installed in the car. All the instruments in the dash are in place and coupled, the steering wheel with the wiring down the column installed and connected and checked. Filled the motor up with water intending to use this for flushing the system and found the drain tap on the radiator was not screwed in properly, could not be done in place so out comes the radiator, tap screwed in and back in again.

With a bit of tongue in cheek I had cleaned and checked the brake and clutch master and clutch slave before putting them in the car, unfortunately these were not OK so were taken to Sterling Clutch and Brake. The brake master and the clutch slave were re-sleeved with stainless and the clutch master replaced. Installed, charged and bled, everything working OK. Always get good service from that company.

Had a trial fit of the assembled windscreen to check how it would sit, the two holes at the door hinges had been covered with filler etc during the fibre glass repairs and painting so these had to be drilled and bolts made for this job. I used long ¼” UNF bolts, drilled 3 nuts to slide down the shank, brazed 2 in line with the head and the other at a point to give the length of thread I needed. These bolts give a better guide than just a normal bolt, and with the confined space it is certainly needed. The screen glass I used was a rejected one that was delaminating that I had been given, the intention being to get a new one before the final installation. Just as well as one of those side bolts was too long and I cracked the corner of the screen. The trial fit showed that some serious packing was going to be needed to get the screen’s position correct. I am told most have washers etc used for this purpose.